Lindsay Moore on Tour | Chicago

It’s just another reason why I love this industry - trends are always changing and it’s exciting to get to check them out, firsthand.

- Lindsay Moore

Last week, Vessel’s Lindsay Moore spent two days in Chicago with Lighting Associates’ Callia Ball, Courtney Sheets and Julie Zobel. The ladies toured two innovative lighting manufacturers: Artemide and Focal Point.

We discussed her tour...

What was the purpose of this specific trip?

Lindsay: As a project architect, it’s vital to keep up with trends, especially when it comes to lighting. Fixtures are imperative to any project – they not only define a space physically, but mentally and emotionally. Any opportunity to educate yourself on what is up-and-coming is worth taking!

You visited Artemide and Focal Point. What was unique about each company?

LM: Artemide, founded in Milan, Italy, offers more high-end designs whereas Focal Point presents buyers with a wide range of fixtures that can meet any budget. Depending on project type and clientele – there is something at each company that would add flair to any space.

You’ve had several years of experience with lighting manufacturers; what was something new you learned?

LM: Something that is becoming more desirable in this industry is the use of both American-made products as well as products that are LEED Certified. Focal Point understands LEED to the core as the headquarters is a LEED Gold certified facility. Focal Point was founded and continues to reside in Chicago – which is fantastic because not only are they supporting our country economically, but they can typically provide their customers one of the shortest turn-around times. Focal Point also has their own UL testing area on campus; therefore, there is minimal wait time to receive UL ratings when creating new lighting fixtures – where normally that process could take between 6-8 weeks.

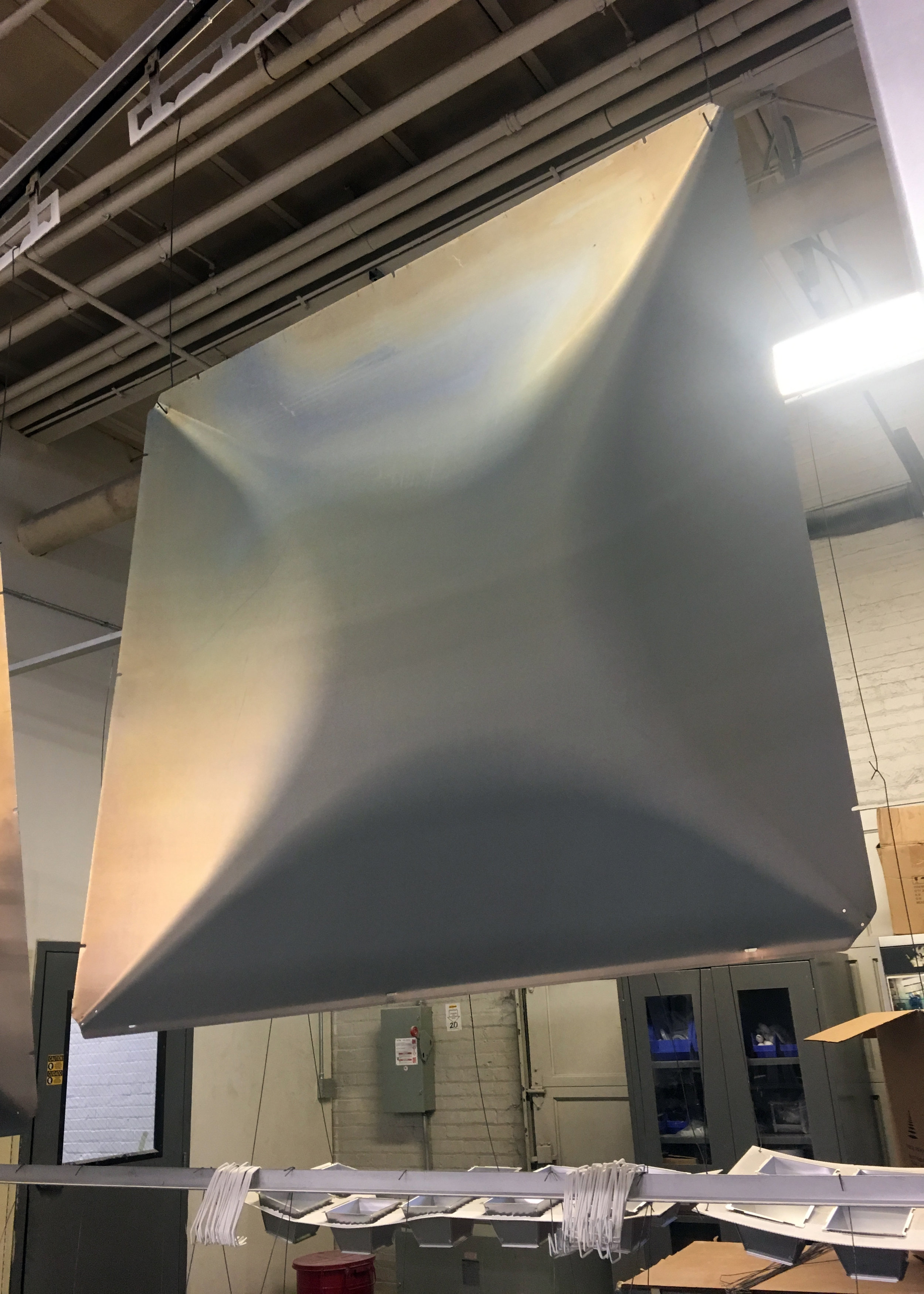

Did you get to catch a glimpse of any behind-the-scenes manufacturing work?

LM: Yes, we were able to check out the actual manufacturing plant for Focal Point. One thing I noticed was the implementation of checks-and-balances – the amount of quality assurance this company provides is outstanding, and of course continues to positively impact their reputation as a preferred lighting manufacturer. They are also beginning to introduce laser cutting as opposed to metal stamping, which will greatly affect how quickly and accurately they can produce certain products.*

*Metal Stamping (Punching) is a forming process that presses metal with a powerful die into a fixed shape (or pattern). Laser cutting is a technology that uses a laser to cut materials into the desired shape (or pattern).

- Katie Luster